Download the Whitepaper

Supply Chain Outlook: What to Expect Near-Future

.png?width=213&height=266&name=Untitled%20design%20(39).png)

An investigation into how supply chains have changed, where they are heading, and how you can prepare.

Get the report to see how supply chains will look in the next 5 years.

Experience the benefits of plastic pallets vs. wood pallets

Wood Pallets

✘ Costly

They can’t nest. They can’t rack. They take up space in trucks and plants, leading to extra transportation costs.

✘ Contaminated

Wood absorsb bacteria and water. Shavings and dust contaminates your shipment and dirty your facility.

✘ Damaged

Nearly a third of wooden pallets require repairs. You pay for wasted product and pass-through repair costs.

✘ Wasteful

Even with repairs, wood pallets last ~3 years, preventing you from reaching sustainability goals.

✘ Non-uniform

Each pallet is unique with bulges, dents, nails and big variations in weight.

✘ Supply chain disruptions

Lost pallets can cause disruptions in your supply chain, a problem that is resolved with trackable plastic pallets.

✘ Foreign bodies

Foreign bodies contribute to inconsistent pallet sizes and are a potential hazard in your supply chain.

✘ Absorbent

Wood pallets absorb liquids, which can pose threat to health and food safety.

✘ Waste space

Bulky wood pallets cause inconsistencies in your supply chain and cost you more space.

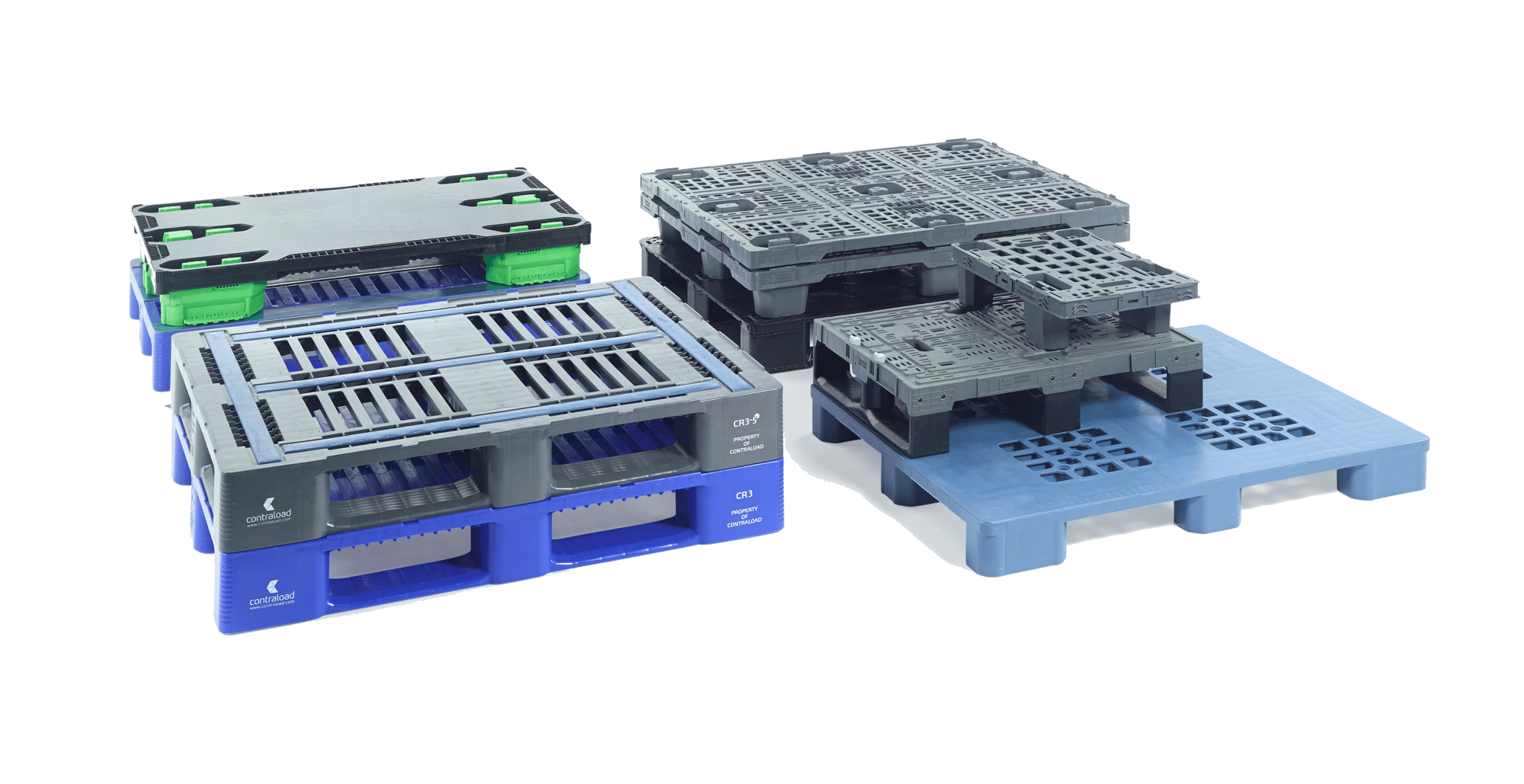

Reusable Plastic Pallets

✓ Economical

Plastic pallets last longer than wooden pallets, making them a cost-effective choice in a well-managed pooled system.

Plastic pallets last longer than wooden pallets, making them a cost-effective choice in a well-managed pooled system.

✓ Food grade

Food grade compliant according to EU directives 10/2011 and 1935/2004, virgin material, no harmful substances used during production. Pallets are also available in recycled material.

Food grade compliant according to EU directives 10/2011 and 1935/2004, virgin material, no harmful substances used during production. Pallets are also available in recycled material.

✓ Hygienic

Because of the smooth surface of a plastic pallet, it is easy to wash and keep clean. Bacteria, fungi and mold have no chance of survival.

✓ Transportation

Plastic pallets are ISPM-15 proof. No more heat-treated wooden pallets for international shipments. Keep it simple and safe.

Plastic pallets are ISPM-15 proof. No more heat-treated wooden pallets for international shipments. Keep it simple and safe.

✓ Consistent sizes

Because plastic pallets are moulded, the sizes and weight are always consistent, causing zero disturbances in your automated material handling systems.

✓ Traceable

RFID tags and even GPRS and IoT technology can be embedded so tracing your pallets is simple and data is readily available.

RFID tags and even GPRS and IoT technology can be embedded so tracing your pallets is simple and data is readily available.

✓ No foreign bodies

No more loose particles or protruding parts, like wood chips, splinters and nails that can cause injuries or product damage. A clean working environment and storage area.

No more loose particles or protruding parts, like wood chips, splinters and nails that can cause injuries or product damage. A clean working environment and storage area.

✓ Non-porous

Plastic pallets don’t absorb water or any other liquids, a huge advantage when working in a clean environment as you avoid contamination risks.

✓ Nestable-rackable

If selecting a nestable pallet, there are significant space savings and efficiency gains with storage and return transport.

Join top suppliers and retailers globally who have already switched to Tosca reusables

make the switch

Upgrade your supply chain with reusable pallets

Wooden pallets are wasteful. Plastic pallets are designed to make your supply chain more efficient.

To see the difference you can experience in your supply chain by making the switch from wooden to plastic pallets, get in touch with our sales team today.